We provide Alya NIC online (apkid: apple.com.istartalya) in order to run this application in our online Android emulator.

Description:

iPhone app Alya NIC download it using MyAndroid.

The app Neon Intelligence Center (NIC) shows real time data from a chenille or fancy yarn manufacturing machine equipped with the Alya new NEON electronic yarn clearers.

Up to 60 clearers can be handled using wireless communication protocol.

The weaving mill is monitored by the NEON optic clearers and the overall behaviour of the plant is easily shown by NIC using graphic charts.

NIC sequentially polls all clearers to update the visualisation of the defects spotted by the clearer on each spindle of the chenille mill.

Relevant production data as well as setting parameters for each clearer can easily be monitored and edited by the user.

The use of NIC is aimed to let the manufacturer achieve a zero defects quality target for yarn production lots, monitoring the behaviour of the entire plant using up to date electronic tools.

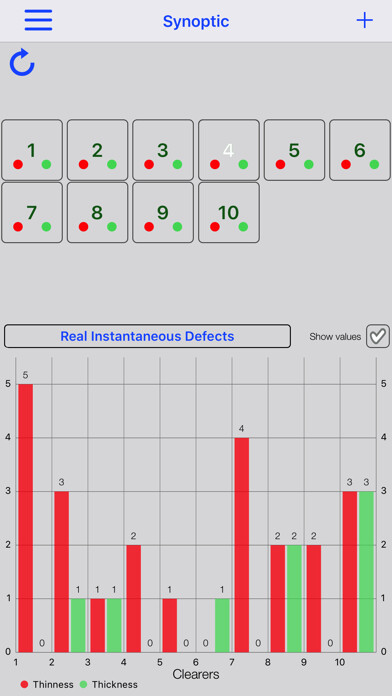

NIC shows graphical reports of all the captured defects in a comprehensive view easy to understand to have a comprehensive glance at the plant behaviour in terms of yarn quality.

NIC makes each clearer to cut the yarn when detects a yarn single defect according to the Real settings.

For each Virtual defect detected instead, according to the Virtual settings, NIC records that defect but does not make cut the yarn.

Real and Virtual defects are Stripbacks (thinness) and Knots (thickness) for four clearing channels:

Instantaneous Defects

the single usual yarn defect to detect, stripback and/or knot

Average Diameter

the clearer makes a long term average of the yarn dimension and checks for dimension steadiness

Yarn Winder

the clearer checks for a sudden change of the yarn dimension after the last cut

Repetitive Defects

the clearer accounts for small but many defects just in sequence and reacts accordingly.

Detailed settings available for each NEON clearer using NIC:

##General

Yarn speed

Caliper dimension

Pause time

Acceleration time

Auto Start

Auto Start Threshold

##Instantaneous Defects

Thick and Thin sensitivity setting.

Thick and Thin defect length setting.

Real and Virtual.

##Average Diameter

Thick and Thin sensitivity setting.

Real and Virtual.

Thick and Thin defect length setting.

Real and Virtual.

Yarn Winder

Thick and Thin sensitivity setting.

Real and Virtual.

##Repetitive Defects

Thick and Thin sensitivity setting.

Real and Virtual.

NIC also shows for each clearer and for each clearing channel:

Real defects (thin and thick cuts)

Virtual defect (thin and thick)

other service and status values

NIC does as well available for each clearer the following facilities:

Cut Command

Address Change

Zeroing

Max/Min light reset

Parameters Copy

Registered Defects Clear

Set Calibration Defaults

NIC app asks for WiFi connection of the iOS to the NEON WiFi Adapter (WFA) device installed in every NEON clearing plant and provided by Alya.

The user is strongly recommended to refer to Alyas service personnel to setup the proper WiFi settings in the iOS device to use with NIC.

For users, to evaluate the NIC facilities, a demo version of the WFA host setting is provided by NIC: the user has to click the menu icon (three blue horizontal lines) entering the word demo as the host address.

This switches on a demo version of the app that emulates a real plant for evaluation purposes.

NOTE: the demo version emulates clearers that only detect Real Instantaneous Defects (~75% thins, ~25% thick) with random Missed Polls.

The charts shown by the app only refer to this.

Using the demo version all commands, to change the clearer Parameters and Other Values shown, run smoothly, but no data are affected and most returns are zeroed.,

MyAndroid is not a downloader online for Alya NIC. It only allows to test online Alya NIC with apkid apple.com.istartalya. MyAndroid provides the official Google Play Store to run Alya NIC online.

©2025. MyAndroid. All Rights Reserved.

By OffiDocs Group OU – Registry code: 1609791 -VAT number: EE102345621.